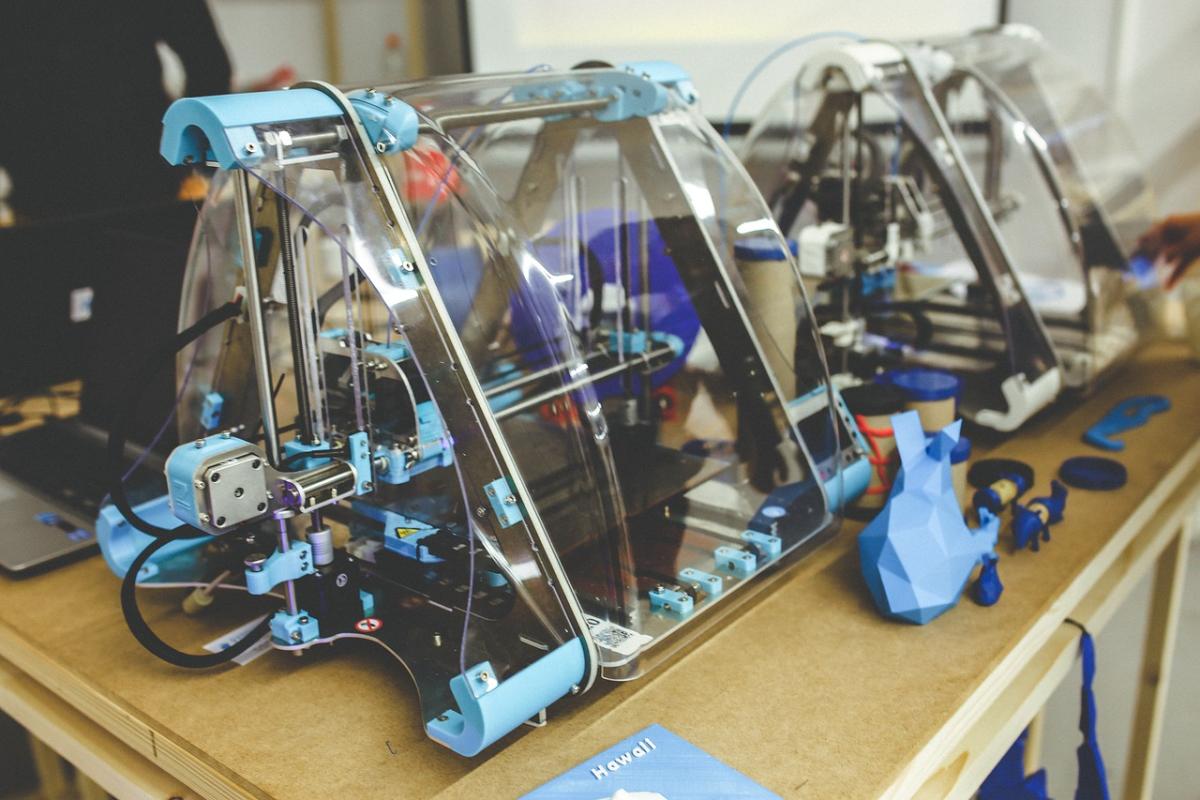

When diving into the world of 3D printing, one of the most exciting parts is exploring the different types of resin available. Each type offers unique properties, making it easier to find the perfect fit for your project.

First up, we have standard resin. This is the go-to choice for many beginners. It cures quickly and produces smooth, detailed prints—great for miniatures and models. It's user-friendly, making it a popular option if you’re just starting out.

If durability is what you need, tough resin might be your best buddy. It's built to withstand stress and impact, so whether you’re making functional parts or prototypes, this resin can handle it. Plus, it doesn’t sacrifice detail, so you get the best of both worlds.

Next, let’s talk about flexible resin. If you want something that can bend without breaking, this is the resin for you. Imagine printing something like phone cases or wearable items. Its rubber-like feel makes it versatile and fun to work with.

Finally, there’s castable resin. This one shines in jewelry making and casting projects. After 3D printing, you can burn it out, leaving a perfect mold for metal, wax, or other materials. It's perfect if you want to create something special and unique. Choose the right resin, and your 3D printing experience just becomes a whole lot better!

Choosing the Right Resin for Your Project

Choosing the right resin for your 3D printing project can feel a bit overwhelming with all the options out there. But don’t worry! Let’s break it down so you can find the perfect match for your needs.

First off, you need to think about what you’re making. Are you creating detailed miniatures, prototyping something, or designing a larger functional part? For intricate designs, you’ll want a resin that can capture fine details—look for a high-resolution resin. If strength and durability are key, then consider a tough resin that can withstand stress and impact.

Next, consider the finish. Some resins provide a glossy look while others might have a matte finish. If you want your prints to look polished right out of the printer, go for a resin known for its smooth finishing. For projects where you plan to paint or detail, a matte resin might be your best bet.

Don’t forget about curing time and post-processing. Some resins cure quickly, while others take a bit longer. Depending on your schedule, you might want to choose a resin that matches your speed needs. And remember, all resins require some post-processing. Make sure you have all your cleaning and curing supplies ready to give your prints the best finish possible!

Lastly, check compatibility with your printer. Not all resins work with every printer, so make sure the one you're eyeing is a good fit. It’s a small step but a crucial one to avoid headaches later on!

Benefits of Using 3D Resin

Using 3D resin has some pretty neat perks that can really take your projects to the next level. First off, resin printers can create intricate details and smooth finishes that filament printers struggle with. If you want to make miniatures or complex designs, resin is your best friend. It captures tiny features beautifully, making your models look professional right out of the printer.

Another major advantage is the variety of resin types available. Want something flexible? There’s resin for that. Need something super tough? You got it. From standard resins to specialty options like castable resin for jewelry making, there’s plenty to choose from. This range lets you pick the perfect material for whatever you’re dreaming up.

Resin printers are often faster than traditional FDM printers. While FDM can take hours or days for big prints, resin can usually get the job done in a fraction of the time. Layer by layer, the process shines, especially for smaller prints where detail matters. You’ll have your creations ready to go much quicker.

Lastly, the setup and clean-up process is straightforward. With the right tools, you can get started quickly and clean up after printing without a huge hassle. Just remember to take safety precautions when working with resin. A little caution goes a long way in ensuring a safe and enjoyable printing experience!

Tips for Working with 3D Resin

Working with 3D resin can be a fun but sometimes tricky experience. Here are some solid tips to make your journey smooth sailing.

First off, always wear gloves when handling resin. It’s a messy business, and getting that stuff on your skin isn’t ideal. Also, a well-ventilated workspace is a must. Open a window or use a fan to keep the air fresh. Safety first!

When mixing resin, take your time. Follow the instructions on the bottle carefully. Measure your resin and hardener accurately. A tiny mistake can lead to a whole lot of trouble. You want that perfect cure!

Don’t forget about the temperature. Resin likes it warm, so if your workspace is chilly, it might affect the curing process. Try to keep things around room temperature for the best results. And if you can, grab a dehumidifier if your area tends to get humid. Resin can show its worst side in sticky situations.

Lastly, post-processing is key. Once you've printed your creations, make sure to wash them thoroughly. Use isopropyl alcohol to clean off any uncured resin. After that, cure your pieces under UV light to really lock in that finish. Trust me, it makes a big difference!